Integrated Bale Wrappers

Integrated Baler Wrapper

THE MOST ADVANCED INTEGRATED BALER WRAPPER RANGE

The new McHale Fusion 4 range has been developed with a focus on operator comfort and machine performance, while still ensuring the renowned simplicity and reliability is maintained.

Our specialist team of engineers have maximised machine intake and output, increased bale density and reduced maintenance intervals to ensure the Fusion 4 range of machines surpasses all your baling and wrapping expectations.

These levels of comfort, when paired with proven features such as the patented bale transfer system and the vertical wrapping ring, enable the McHale Fusion 4 range of machines to offer durability, reliability and high output to the end user.

Overview

The McHale Fusion 4 is a robust, fully automatic, integrated baler wrapper recognised worldwide for its unique patented bale transfer, vertical wrapping ring and high output.

The machine is equipped with a 25-knife chopping unit, automatic progressive greasing system and a servo operated load sensing control valve, which when combined with the Expert Plus control console, makes the baling and wrapping process fully automatic. The machine is fitted with 560/60-22.5 tyres as standard.

Patented Bale Transfer

When the netting process is complete the bale chamber splits horizontally. As the top section of the bale chamber moves up, the lower section of the bale chamber simultaneously moves up and out, transferring the bale onto the wrapping platform.

Vertical Wrapping Ring

The vertical wrapping ring is fitted with two 750 mm dispensers, which take approximately 18 seconds to apply 4 layers of film and approximately 24 seconds to apply 6 layers of film in ideal working conditions. In ideal operating conditions, this means that the wrapping platform is always waiting for the next bale.

Standard Features

| 2.1m Profi-Flo Pick-Up | 25 Knife Heavy Duty Feed Rotor | Drop Floor Unblocking System |

| 50 & 55 mm Bale Chamber Bearings* | 1¼” Chain on the Bale Chamber | Automatic Progressive Greasing System |

| Automatic Oiling System | Expert Plus Control Console (Large Graphic Display) | 560/60-22.5 Tyres |

| 18 Roller Bale Chamber | 4 Bar Pivot Stretch Netter | Vertical Wrapping Ring with Film Break Sensors |

* 55 mm bearings fitted to rollers with long shafts and double sprockets

Integrated Baler Wrapper

THE MOST ADVANCED INTEGRATED BALER WRAPPER RANGE

The new McHale Fusion 4 range has been developed with a focus on operator comfort and machine performance, while still ensuring the renowned simplicity and reliability is maintained.

Our specialist team of engineers have maximised machine intake and output, increased bale density and reduced maintenance intervals to ensure the Fusion 4 range of machines surpasses all your baling and wrapping expectations.

These levels of comfort, when paired with proven features such as the patented bale transfer system and the vertical wrapping ring, enable the McHale Fusion 4 range of machines to offer durability, reliability and high output to the end user.

Overview

The McHale Fusion 4 Pro is a fully automatic integrated baler wrapper which is controlled using ISOBUS. The McHale Fusion 4 Pro provides new levels of operator comfort with it’s easy-to-use control system, in-cab net & density adjustment, camera, and faster wrapping speeds along with a host of other new features.

The McHale Fusion 4 Pro uses net to bind the bale in the chamber and features the McHale patented bale transfer and vertical wrapping ring, which are noted for their reliability, speed and positive bale transfer in hilly conditions.

In-Cab Adjustment

The ISOBUS control terminal allows for bale density to be adjusted from the comfort of the tractor cab. Depending on the crop and conditions, the operator can also adjust the number of layers of net on the control terminal.

Drop Floor Unblocking

The drop floor unblocking system is fitted with an automatic unblocking function as standard. When connected to an ISOBUS tractor, the Auto Unblock feature lowers the floor when a blockage is detected. Once the operator restarts the PTO and clears the blockage, the drop floor will raise to its original position.

Control Terminals

The McHale Fusion 4 Pro is fitted with ISOBUS as standard. For customers without an ISOBUS tractor, an optional ISO-PLAY 7 or ISO-PLAY 12 terminal can be used. Through the ISOBUS tractor’s terminal or McHale’s ISO-PLAY terminals, the operator is provided with clear indicators of machine performance and allows for increased levels of monitoring, through the graphic display.

Camera Display as Standard

The McHale Fusion 4 Pro comes fitted with a camera as standard to monitor the transfer and wrapping operation at the rear of the machine. When using an ISO-PLAY terminal, this camera automatically displays on the control terminal in the tractor cab when the bale is being transferred to the wrapping table, at the beginning of the wrapping cycle and when the bale is about to be tipped.

Standard Features

| 2.1m Profi-Flo Pick-Up | 25 Knife Heavy Duty Feed Rotor | Drop Floor Unblocking System |

| 50 & 55 mm Bale Chamber Bearings* | 1¼” Chain on the Bale Chamber | Automatic Progressive Greasing System |

| Automatic Oiling System (with Lube Interval Adjustment & Alarm) | ISOBUS Compatibility | 560/60-22.5 Tyres |

| 18 Roller Bale Chamber | 4 Bar Pivot Stretch Netter | Vertical Wrapping Ring with Film Break Sensors |

* 55 mm bearings fitted to rollers with long shafts and double sprockets

Integrated Baler Wrapper

THE MOST ADVANCED INTEGRATED BALER WRAPPER RANGE

The new McHale Fusion 4 range has been developed with a focus on operator comfort and machine performance, while still ensuring the renowned simplicity and reliability is maintained.

Our specialist team of engineers have maximised machine intake and output, increased bale density and reduced maintenance intervals to ensure the Fusion 4 range of machines surpasses all your baling and wrapping expectations.

These levels of comfort, when paired with proven features such as the patented bale transfer system and the vertical wrapping ring, enable the McHale Fusion 4 range of machines to offer durability, reliability and high output to the end user.

Overview

The McHale Fusion 4 Plus is a fully automatic integrated baler wrapper which can apply film or net wrap to the barrel of the bale, delivering optimum bale shape and bale density. The Fusion 4 Plus can provide high quality fodder through the use of the film binding system, resulting in better silage quality and easier feed out.

The machine is equipped with a patented bale transfer system and a vertical wrapping ring. These two McHale patents deliver maximum output whilst keeping the machine short and compact at 5.8 metres in length. The machine is equipped with a 25 knife-chopping unit and uses ISOBUS software.

Film Binding

The concept of putting film on the barrel of the bale is known as “Film binding technology.” The plastic, which is applied to the barrel of the bale forms an additional layer of wrap across the largest surface of the bale, whilst also binding the bale together.

The film which is applied to the barrel of the bale can be stretched according to the manufacturers recommendations which is a higher ratio than can be achieved with net wrap. This additional layer of film on the barrel of the bale provides higher quality silage as the film can be stretched more than net. This in turn, expels more air, resulting in better silage quality.

By using film to bind the bale together, removal and recycling of the film is made easier as the farmer is only left with one form of waste to recycle and can avoid the unpleasant and time consuming job of separating net from the plastic.

Patented Bale Transfer

When the bale is bound in the bale chamber, the bale chamber splits horizontally. As the top section of the bale chamber moves up, the lower section of the bale chamber simultaneously moves up and out, transferring the bale onto the wrapping platform.

Control Terminals

The McHale Fusion 4 Plus is fitted with ISOBUS as standard. For customers without an ISOBUS tractor, an optional ISO-PLAY 7 or ISO-PLAY 12 terminal can be used. Through the ISOBUS tractor’s terminal or McHale’s ISO-PLAY terminals, the operator is provided with clear indicators of machine performance and allows for increased levels of monitoring, through the graphic display.

Standard Features

| 2.1m Profi-Flo Pick-Up | 25 Knife Heavy Duty Feed Rotor | Drop Floor Unblocking System |

| 50 & 55 mm Bale Chamber Bearings* | 1¼” Chain on the Bale Chamber | Automatic Progressive Greasing System |

| Automatic Oiling System (with Lube Interval Adjustment & Alarm) | ISOBUS Compatibility | 560/60-22.5 Tyres |

| 18 Roller Bale Chamber | Film or Net Binding | Vertical Wrapping Ring with Film Break Sensors |

* 55 mm bearings fitted to rollers with long shafts and double sprockets

Variable Chamber Integrated Baler Wrapper

The McHale variable chamber baler range is made up of V6, V8 and Fusion Vario machines. The range consists of 5 models;

- V6740 – Non-Chopper Baler

- V6750 – Chopper Baler

- V8940 – High-Capacity Non-Chopper Baler

- V8950 – High-Capacity Chopper Baler

- Fusion Vario – Integrated Baler Wrapper

Offering innovative ideas to allow you to work smarter, whilst achieving more output, the McHale name has become synonymous with the production of robust and reliable machines, making McHale the number one choice for professional users.

Overview

The McHale Fusion Vario is a fully automatic variable chamber integrated baler wrapper, which consists of a high output baler and a vertical wrapping ring. The machine benefits from two unique patents; a patented bale transfer system and a patented vertical wrapping ring.

The Fusion Vario also has the ability to make bales of hay and straw from 0.6m to 1.68m (2′ – 5′ 6 “) but in haylage or silage, it produces bales from 1m to 1.45m (3′ 3 ” – 4′ 8 “) to allow for wrapping.

Advantages of the Fusion Vario

ONE MACHINE

The Fusion Vario provides the operator with the flexibility to produce various size bales without the need to return to the yard to change machines for baling different types of crop over the course of a day. As it is an integrated baler wrapper, only one operator and tractor is required to carry out the task of baling and wrapping which leads to reduced costs in labour.

REDUCED CROP LOSS

The single belt on the McHale Fusion Vario reduces crop loss compared to multiple belts which is particularly beneficial when baling short chopped crops such as alfalfa.

BALE ONLY PROGRAMME

When baling hay or straw, the operator has the ability to carry and place bales in pairs of two for easy collection.

Standard Features:

| 2.1m Pick-Up | Crop Roller | iTouch Control System |

| Inbuilt Camera System | Drop Floor Unblocking System | Double Drive Variable Bale Chamber |

| 15 Knife Chopper Unit with Heavy Duty Rotor | Single Belt Bale Chamber with Endless Belt | Bale Shape Indicators |

| Patented Bale Transfer Delivering Higher Output | High Speed Vertical Wrapping Ring | Fully Automatic Operation |

| 3-Endless Belts

Single Belt (Optional) | Mechanical Tailgate Locking | Drop Floor Sensor |

| * 55 mm bearings fitted to rollers with long shafts and double sprockets | ||

Variable Chamber Integrated Baler Wrapper

THE MOST ADVANCED INTEGRATED BALER WRAPPER RANGE

The McHale Fusion range has been developed with a focus on operator comfort and machine performance, while still ensuring the renowned simplicity and reliability is maintained. Our specialist team of engineers have maximised machine intake and output, increased bale density and reduced maintenance intervals to ensure the Fusion range of machines surpasses all your baling and wrapping expectations.

These levels of comfort, when paired with proven features such as the patented bale transfer system and the vertical wrapping ring, enable the McHale Fusion range of machines to offer durability, reliability and high output to the end user.

Overview

The MCHALE FUSION VARIO PLUS is a fully automatic integrated baler wrapper which can apply film or net wrap to the barrel of the bale, delivering optimum bale shape and bale density. The Vario Plus can provide high quality fodder through the use of the film binding system, resulting in better quality silage and easier feed out. This machine provides a number of benefits as the task of baling and wrapping can be carried out using one machine. There is also a labor saving, as one operator, one tractor and one machine can complete baling and wrapping duties. The McHale Fusion Vario Plus also has the ability to make bales of hay and straw from 0.6m to 1.68m (2’–5’6″) but in haylage or silage, it produces bales from 1m to 1.45m (3 ‘ 3 “–4 ‘8 “) to allow for wrapping.

It features two unique patents; a patented bale transfer system and a patented vertical wrapping ring. The machine is ISOBUS compatible and can be operated through the tractor terminal or ISO-Play 7 or 12 terminals.

Standard Features

| 2.1m Profi-Flo Pick-Up | Film or Net Binding | ISOBUS/ ISO-Play |

| 2x Inbuilt Camera System | Drop Floor Unblocking System | Double Drive Variable Bale Chamber |

| 15 Knife Chopper Unit with Heavy-Duty Rotor | Single Belt Bale Chamber with Endless Belt | Bale Shape Assist Indicators |

| Patented Bale Transfer Delivering Higher Output | High Speed Vertical Wrapping Ring | Spring Tine Crop Roller |

Film Binding

The concept of putting film on the barrel of the bale is known as “Film Binding Technology.” The plastic, which is applied to the barrel of the bale forms an additional layer of wrap across the largest surface of the bale, whilst also binding the bale together.

The film which is applied to the barrel of the bale can be stretched according to the manufacturers recommendations which is a higher ratio than can be achieved with net wrap. This additional layer of film on the barrel of the bale provides higher quality silage as the film can be stretched more than net. This in turn, expels more air, resulting in better silage quality.

By using film to bind the bale together, removal and recycling of the film is made easier as the farmer is only left with one form of waste to recycle and can avoid the unpleasant and time consuming job of separating net from the plastic.

Patented Bale Transfer

When the bale is bound in the bale chamber, the bale chamber splits horizontally. As the top section of the bale chamber moves up, the lower section of the bale chamber simultaneously moves up and out, transferring the bale onto the wrapping platform.

Control Terminals

The McHale Fusion Vario Plus is fitted with ISOBUS as standard. For customers without an ISOBUS tractor, an optional ISO-PLAY 7 or ISO-PLAY 12 terminal can be used. Through the ISOBUS tractor’s terminal or McHale’s ISO-PLAY terminals, the operator is provided with clear indicators of machine performance and allows for increased levels of monitoring, through the graphic display.

Fixed Chamber Round Balers

F5-540 – Non Chopper Fixed Chamber Baler

Offering innovative ideas to allow you to work smarter, whilst achieving more output, the McHale name has become synonymous with the production of robust and reliable machines, making McHale the number one choice for professional users.

Download Product PDF

Overview

The McHale F5-540 is a semiautomatic, non-chopper Fixed Chamber Baler, equipped with a star shaped feed rotor to quickly and efficiently move crop from the pick-up into the bale chamber, maximising baler throughput and performance. Central grease blocks are fitted on the machine for greasing, whilst oiling is controlled through the continuous oiling system. The F5-540 is also equipped with a Wizard Control Console. The machine is fitted with 13.5/7.5-430.9 tyres as standard.

Standard Features:

| 2.1m Profi-Flo Pick-Up | Non-Chopper Twin Finger Rotor | Drop Floor Unblocking System |

| 18 Roller Bale Chamber | 50mm & 55mm Bale Chamber Bearings* | 1′-1/4″ Chain on the Bale Chamber |

| Centralised Greasing Blocks(Manual Greasing) | Dual Feed Net System | Continuous Oiler System |

Wizard Control Console (4 Digit Display) | 13.5/7.5-430.9 Tyres | Bale Kicker |

| *Bearings are 55mm double raced on the main load points | ||

15 Knife Fixed Chamber Baler

Offering innovative ideas to allow you to work smarter, whilst achieving more output, the McHale name has become synonymous with the production of robust and reliable machines, making McHale the number one choice for professional users.

Download Product PDF

Overview

The McHale F5-550 is a semiautomatic, 15 knife chopper Fixed Chamber Baler, which comes fitted with automatic progressive greasing as standard. It is equipped with a i-Control 5 terminal, which allows the operator to control features such as drop floor and knife position. Bale density can now be adjusted on the terminal in the tractor cab. The machine is fitted with 500/50-17 tyres as standard.

Standard Features:

| 2.1m Profi-Flo Pick-Up | 15 Knife Chopper Rotor | Drop Floor Unblocking System |

| 18 Roller Bale Chamber | 50mm & 55mm Bale Chamber Bearings* | 1′-1/4″ Chain on the Bale Chamber |

| Automatic Progressive Greasing System | Dual Feed Net System | Continuous Oiler System |

| i-Control 5 Console or ISOBUS (Optional) | 500/50-17 Tyres | 15 Knife Chopper Unit |

| Knife Pressure Display | Knife Position Sensor | Drop Floor Sensor |

| *Bearings are 55mm double raced on the main load points | ||

25 Knife Chopper Baler with Film Binding Technology

Offering innovative ideas to allow you to work smarter, whilst achieving more output, the McHale name has become synonymous with the production of robust and reliable machines, making McHale the number one choice for professional users.

Download Product PDF

Overview

The McHale F5-560 PLUS is a fully automatic Fixed Chamber Baler equipped with load sensing hydraulics and a 25 knife chopper unit. It is equipped with a film binding system that applies film to the barrel of the bale in the bale chamber. For hay or straw, net can be used. The McHale patented film application system ensures consistent film stretch, reliable film application and delivers optimum bale shape and bale density. The machine is fitted with 500/50-22.5 tyres as standard.

Standard Features:

| 2.1m Profi-Flo Pick-Up | 25 Knife Chopper Rotor | Drop Floor Unblocking System |

| 18 Roller Bale Chamber | 50mm & 55mm Bale Chamber Bearings | 1′-1/4″ Chain on the Bale Chamber |

| Automatic Progressive Greasing System | High Performance Net/Film Binding System | Continuous Oiler System |

ISOBUS / ISO-PLAY | 500/50-22.5 Tyres | 25 Knife Chopper Unit |

| Knife Pressure Display | Knife Position Sensor | Automatic Tailgate Opening & Closing |

| 2 x Cameras for Film Monitoring & Bale Ejection | ||

| *Bearings are 55mm double raced on the main load points | ||

25 Knife Chopper Baler with Film Binding Technology

Offering innovative ideas to allow you to work smarter, whilst achieving more output, the McHale name has become synonymous with the production of robust and reliable machines, making McHale the number one choice for professional users.

Download Product PDF

Overview

Overview

The McHale F5-560 PLUS is a fully automatic Fixed Chamber Baler equipped with load sensing hydraulics and a 25 knife chopper unit. It is equipped with a film binding system that applies film to the barrel of the bale in the bale chamber. For hay or straw, net can be used. The McHale patented film application system ensures consistent film stretch, reliable film application and delivers optimum bale shape and bale density. The machine is fitted with 500/50-22.5 tyres as standard.

Standard Features:

| 2.1m Profi-Flo Pick-Up | 25 Knife Chopper Rotor | Drop Floor Unblocking System |

| 18 Roller Bale Chamber | 50mm & 55mm Bale Chamber Bearings | 1′-1/4″ Chain on the Bale Chamber |

| Automatic Progressive Greasing System | High Performance Net/Film Binding System | Continuous Oiler System |

ISOBUS / ISO-PLAY | 500/50-22.5 Tyres | 25 Knife Chopper Unit |

| Knife Pressure Display | Knife Position Sensor | Automatic Tailgate Opening & Closing |

| 2 x Cameras for Film Monitoring & Bale Ejection | ||

| *Bearings are 55mm double raced on the main load points | ||

Variable Chamber Round Balers

V6740 – Non Chopper Variable Chamber Baler

Overview

The McHale V6740 is a non-chopper variable chamber baler capable of producing bales from 0.6–1.68m (2’–5′ 6″). It is equipped with a high intake, twin finger feed rotor to ensure even and efficient crop flow to the bale chamber.

The V6740 is driven by a primary drive system for optimum bale formation. Central grease blocks are fitted on the machine for greasing whilst oiling is controlled through the continuous oiling system which is driven from the gearbox. Net and bale density can be adjusted through the Expert Plus Control Console.

The machine is fitted with 460/65-20 tyres as standard.

Standard Features:

| 2.1m Profi-Flo Pick-Up | Heavy Duty Feed Rotor | Drop Floor Unblocking System |

| 50 mm Bale Chamber Bearings* | 1¼” Chain on the Bale Chamber | Centralised Greasing Blocks (Manual Greasing) |

| Continuous Oiling System | Expert Plus Control Console | 460/65/20 Tyres |

| High Performance Netter | Bale Kicker | Mechanical Tailgate Locking |

| Drop Floor Sensor | 3-Endless Belts / Single Belt (Optional) | Bale Shape Assist Indicators |

| * 55 mm bearings fitted to rollers with long shafts and double sprockets | ||

Overview

The McHale V6750 is a semi-automatic variable chamber baler capable of producing bales from 0.6–1.68m (2’–5’6″).

The machine is fitted with a 15-knife chopper unit and heavy-duty rotor. A double drive system aids belt rotation and bale formation to allow the machine to operate in the toughest of conditions.

The machine comes with centralised grease blocks as standard. Automatic greasing is available as an optional extra. Net and bale density can be adjusted from the cab through the Expert Plus control console. The machine is fitted with 500/50-22.5 tyres as standard.

Standard Features:

| 2.1m Profi-Flo Pick-Up | 15 Knife Chopper with Heavy Duty Rotor | Drop Floor Unblocking System |

| 3-Endless Belts | Centralised Greasing Blocks (Manual Greasing) | Continuous Oiling System |

| High Performance Stretch Netter | Mechanical Tailgate Locking | 1¼” Chain on the Bale Chamber |

| Expert Plus Control Console | 50mm (2″) Double Race Chamber Bearings | Knife Pressure Display |

| Knife Position Sensor | Drop Floor Sensor | 500/50/22.5 Tyres |

| Bale Kicker | ||

Overview

The McHale V6760 is a fully automatic machine fitted with a 15-knife chopper unit and heavy-duty rotor. As the highest spec machine in the range, it is ISOBUS compatible with the option of using McHale’s ISO-Play 7 or ISO-Play 12 terminals, to allow the operator to experience the highest level of customisation and machine performance and produces a bale from 0.6m (2’) up to 1.68m (5’6”)

Standard Features:

| 2.1m Profi-Flo Pick-Up | 15 Knife Chopper with Heavy Duty Rotor | Drop Floor Unblocking System |

| 3-Endless Belts | Automatic Greasing | Continuous Oiling System |

| High Performance Stretch Netter | Mechanical Tailgate Locking | 1¼” Chain on the Bale Chamber |

| ISOBUS/ISO-Play | 50mm (2″) Double Race Chamber Bearings | Knife Pressure Display |

| Knife Position Sensor | Drop Floor Sensor | 500/50/22.5 Tyres |

| Active Bale Kicker | ||

Overview

The McHale V8940 is a high-capacity, non-chopper variable chamber baler capable of producing bales from 0.6–1.9m (2’–6’3″). It is equipped with a high intake feed rotor to ensure even and efficient crop flow to the bale chamber.

The V8940 is driven by a primary drive system for optimum bale formation using 3-endless belts. Central grease blocks are fitted on the machine for greasing whilst oiling is controlled through the continuous oiling system which is driven from the gearbox. Net and bale density can be adjusted through the Expert Plus Control Console.

The machine is fitted with 460/65-20 tyres as standard.

Standard Features:

| 2.1m Pick-Up | High Intake Feed Rotor | Drop Floor Unblocking System |

| 50 mm Bale Chamber Bearings* | 1¼” Chain on the Bale Chamber | Centralised Greasing Blocks (Manual Greasing) |

| Continuous Oiling System | Expert Plus Control Console | 460/65/20 Tyres |

| High Performance Netter | Bale Kicker | Mechanical Tailgate Locking |

| 3-Endless Belts | Drop Floor Sensor | |

| * 55 mm bearings fitted to rollers with long shafts and double sprockets | ||

Overview

The McHale V8950 is a high capacity, semi-automatic variable chamber baler which is fitted with a 15-knife chopper unit and heavy-duty rotor. It is capable of producing bales from 0.6–1.9m (2’–6’3″).

A double drive system aids belt rotation and bale formation to allow the machine to operate in the toughest of conditions. The machine comes with centralised grease blocks as standard. Automatic greasing is available as an optional extra. Net and bale density can be adjusted from the cab through the Expert Plus control console.

The machine is fitted with 500/50-22.5 tyres as standard.

Standard Features:

| 2.1m Pick-Up | 15 Knife Chopper Feed Rotor | Drop Floor Unblocking System |

| 50 mm Bale Chamber Bearings* | 1¼” Chain on the Bale Chamber | Centralised Greasing Blocks (Manual Greasing) |

| Continuous Oiling System | Expert Plus Control Console | 500/50/22.5 Tyres |

| High Performance Netter | Bale Kicker | Mechanical Tailgate Locking |

| 3-Endless Belts | Drop Floor Sensor | |

| * 55 mm bearings fitted to rollers with long shafts and double sprockets | ||

V8960 Fully Automatic High-Capacity Chopper Baler

Download Product PDFOverview

The McHale V8960 is a fully automatic machine fitted with a 15-knife chopper unit and heavy-duty rotor. As the highest spec machine in the range, it is ISOBUS compatible with the option of using McHale’s ISO-Play 7 or ISO-Play 12 terminals, to allow the operator to experience the highest level of customisation and machine performance.

The McHale V8960 baler is the latest advancement in the variable chamber baler range from McHale. Expanding on the V8 range which produces a bale from 0.6m (2’) up to 1.9 m (6’3”) . The V8960 is fully automatic to provide the operator with a high output and easy to operate machine. Utilising the latest technology, the operator simply has to pause on the swath while the machine binds the bale with net before automatically opening and closing the chamber door to eject the bale and resume baling.

In designing the McHale V8960 fully automatic baler, user friendliness was at the forefront of the machine’s development. The 60 series is the highest spec machine in the V8 range and provides the operator with the following functionality: Active Density Control, Intelli-Chamber for a faster bale release and Active Bale Kicker

Standard Features:

| 2.1m Profi- Flo Pick-Up | 15 Knife Chopper Unit with Heavy Duty Rotor | Drop Floor Unblocking System |

| 3-Endless Belts | Automatic Greasing | Continuous Oiler System |

| High Performance Stretch Net System | 50mm (2″) Double Race Chamber Bearings | 1¼” Chain on the Bale Chamber |

| ISOBUS/ ISO-Play | Mechanical Tailgate Locking | Knife Pressure Display |

| Knife Position Sensor | Drop Floor Sensor | 500/50/22.5 Tyres |

| Active Bale Kicker | ||

Round Bale Wrappers

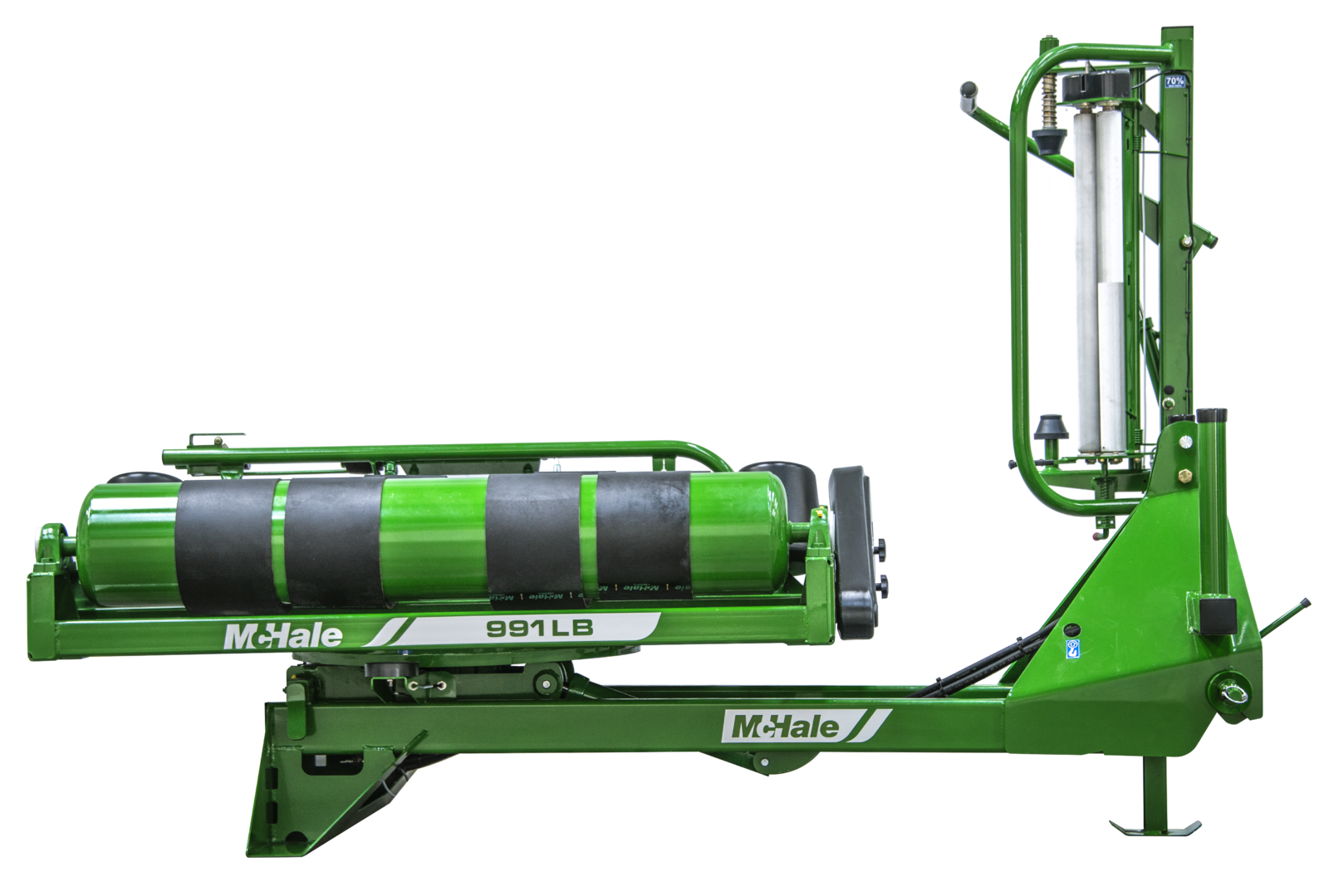

991 LB Single Dispenser Linkage Wrapper

McHale’s round bale wrapper range has been designed with the demands of today’s farmer and contractor in mind. This common-sense approach to design ensures that each machine’s operation is kept simple and user friendly.

Farmers and contractors all over the world are under pressure to reduce costs and increase output. To help with this, McHale concentrate on features like the patented hydraulic ground supported bale damper system, patented high-speed transfer system, patented tip rollers, hydraulically operated cut & hold system, 750mm dispensers and high specification components.

These features ensure long working life, reliability and a machine rugged enough to handle the toughest crops, heaviest bales and roughest ground conditions.

Download Product PDFOverview

The McHale 991 L range of linkage round bale wrappers is the first choice for farmers and contractors who are interested in wrapping bales at the storage site. The 991 L range offers the perfect blend of tried and tested technology with solid construction and reliable performance. There are three models in the 991 linkage round bale wrapper range.

The 991 LB is a manually operated machine where four individual levers control all wrapping functions. Powered by either a tractor or an independent power pack, the 991 LB control valve can either be mounted beside the dispenser post or just inside the tractor cab. The control unit measures the revolutions per minute and monitors the number of layers as they are being applied to the bale. The control unit enables the operator to change the number of film layers and store bale totals from different jobs.

Standard Features

| 750mm aluminum dispenser | Consistent film stretch, which maximises film usage | Quick Fit Dispenser |

| Hydraulically Operated Cut & Hold | A smooth wrapping seal is guaranteed as the machine delivers a 50% overlap | Wrapping table is constructed of four heavy-duty endless belts, which ensure smooth and consistent bale rotation |

Technical Specification

| Transport Length | 2.8 m (9’2″) |

| Transport Width | 1.65 m (5’5″) |

| Transport Height | 1.94 m (6’4″) |

| Height to Top of Rollers | 0.83 m (2’9″) |

| Weight (unladen) | 800 kg (1764 lbs) |

991 BE Fully Automatic Trailed Wrapper

McHale’s round bale wrapper range has been designed with the demands of today’s farmer and contractor in mind. This common-sense approach to design ensures that each machine’s operation is kept simple and user friendly.

Farmers and contractors all over the world are under pressure to reduce costs and increase output. To help with this, McHale concentrate on features like the patented hydraulic ground supported bale damper system, patented high-speed transfer system, patented tip rollers, hydraulically operated cut & hold system, 750mm dispensers and high specification components.

These features ensure long working life, reliability and a machine rugged enough to handle the toughest crops, heaviest bales and roughest ground conditions.

Download Product PDFOverview

The McHale 991 BE is the top of the range fully automatic, electronic, single dispenser machine in the 991 B Range. The machine features an Auto Load function which automatically loads the bale on the wrapping table. The fully automated Expert electronic control console allows the operator to select from 3 cycle options:

| Automatic Wrapping Cycle (Manual load & tip) | Automatic Load and Wrap Cycle (Manual tip) | Automatic Load – Wrap and Tip Cycle |

Standard Features:

| Expert Control Console (Fully automatic cycle) | Auto Load Lift Arm Function | Film Break Sensor |

| Automatic Cut & Hold System | McHale Patented Ground Supported Damper | Capacity to carry 7 rolls of film (6 & 1) |

| 750mm Quick Fit Film Dispenser | Ability to static wrap when using the optional remote control | |

| 2.1m Profi-Flo Pick-Up | 15 Knife Chopper with Heavy Duty Rotor | Drop Floor Unblocking System |

| 3-Endless Belts | Centralised Greasing Blocks (Manual Greasing) | Continuous Oiling System |

| High Performance Stretch Netter | Mechanical Tailgate Locking | 1¼” Chain on the Bale Chamber |

| Expert Plus Control Console | 50mm (2″) Double Race Chamber Bearings | Knife Pressure Display |

| Knife Position Sensor | Drop Floor Sensor | 500/50/22.5 Tyres |

| Bale Kicker | ||

Technical Specification

| Transport Length | 5.7 m (18’8″) |

| Transport Width | 2.45 m (8′) |

| Transport Height | 2.46 m (8’1″) |

| Height to Top of Rollers | 1.25 m (4’1″) |

| Weight (unladen) | 1870 kg (4123 lbs) |

991 High Speed Twin Dispenser Round Bale Wrapper

McHale’s round bale wrapper range has been designed with the demands of today’s farmer and contractor in mind. This common-sense approach to design ensures that each machine’s operation is kept simple and user friendly.

Farmers and contractors all over the world are under pressure to reduce costs and increase output. To help with this, McHale concentrate on features like the patented hydraulic ground supported bale damper system, patented high-speed transfer system, patented tip rollers, hydraulically operated cut & hold system, 750mm dispensers and high specification components.

These features ensure long working life, reliability and a machine rugged enough to handle the toughest crops, heaviest bales and roughest ground conditions.

Overview

The McHale 991 High Speed sets the pace for efficient and effective round bale wrapping, with the hydraulically operated cut and hold system, reducing wrapping time with it’s twin dispensers and Patented Ground Supported Damper System. The 991 High Speed delivers tightly wrapped bales which seal and preserve the crop, with all it’s natural juices, ensuring increased nutritional value. The twin 750mm aluminum dispensers maintain a consistent stretch, which maximises film usage. The dispenser units consist of two aluminium rollers, which are geared to each other with robust steel gears of different ratios. The two dispensers on the 991 High Speed are stepped so that there is an overlap where the two sheets of plastic come together.

Standard Features:

| Expert Control Console (Fully automatic cycle) | Auto Load Lift Arm Function | Film Break Sensors |

| Automatic Cut & Hold System | McHale Patented Ground Supported Damper | Capacity to carry 8 rolls of film (6 & 2) |

| 750mm Twin Film Dispensers | Quick Fit Dispenser Film Change | |

991 High Speed Technical Table

| Transport Length | 5.7 m (18’8″) |

| Transport Width | 2.45 m (8’1″) |

| Transport Height | 2.46 m (8’1″) |

| Height to Top of Rollers | 1.25 m (4’1″) |

| Weight (unladen) | 1900 kg (4189 lbs) |

Orbital High Speed Twin Dispenser Round Bale Wrapper

The McHale Orbital high-speed round bale wrapper harnesses the proven vertical wrapping ring technology used in the McHale Fusion such as the patented high-speed transfer system and the patented tip roller to deliver a high-output, low-maintenance wrapper which is capable of keeping up with multiple balers.

These patents ensure high output and superior levels of forage quality are achieved.

Overview

The McHale Orbital is a high-speed round bale wrapper which delivers an even and consistent overlap and achieves optimum levels of fodder preservation and quality.

Standard Features

| Fully Automatic Operation | Patented High-Speed Bale Loading | High-Speed Vertical Wrapping Ring |

| Wrap Bales from 1.1m – 1.45m (3’7″ to 4’9″) | Proven and Reliable Cut & Hold System | Gentle Bale Tip after Wrapping |

| Film Break Sensors | Facility to Wrap with One Roll Easy Film Loading | Expert Plus Control Console |

Technical Specification

| Transport Length | 4.35 m (14′ 3″) |

| Transport Width | 2.74 m (9′)* |

| Transport Height | 3.0 m (9′ 3″) |

| Height to Top of Rollers | N/A |

| Weight (unladen) | 2400 kg (5391 lbs) |

Square Balers

995 TSR Square Bale Wrapper

The McHale 995 TSR is a trailed, single dispenser, fully automatic remote control square bale wrapper range which is a practical and versatile solution for wrapping large square bales.

With the usual McHale common sense design, quality components and precision engineering the 995 TSR square bale wrapper is the trusted choice for farmers who want high output and consistent performance for use in static locations.

Download Product PDFOverview

On the McHale 995 TSR square bale wrapper, the rotating rollers ensure an even rotation of the bale and the efficient application of the film. With a simple adjustment the 995 TSR will equally and efficiently wrap large round bales.

The 995 TSR square bale wrapper provides an operator with the flexibility to mount a hydraulic power pack on the front of the machine for transportation and operation. The 995 TSR also features a trailed drawbar and transportation wheels. The 995 TSR can also be operated from the loading tractor by remote control, allowing for one man operation of the loading, wrapping and stacking functions.

Like all McHale square bale wrappers, the high output 995 TSR square bale wrapper will give you a tightly wrapped bale that contains all the natural juices for increased nutritional value while improving environmental protection.

Standard Features:

| Ability to wrap round or square bales | Max round bale size 150cm x150cm ( 5′ x 5′) | Radio Remote Control |

| Hydraulic Cut & Hold | Quick Fit 750mm Dispensers | Working table speed of up to 30 rotations/minute |

| Oscillating Rollers | Adjustable bobbins for different size bales | Spare Film Roll Holders |

| Can be used by a tractor or powerpack | ||

Technical Specification

| Total Length | 3.1 m / 10’2” |

| Transport Width | 1.73 m / 5’8” |

| Height to top of rollers | 0.97 m / 3’2” |

| Weight (unladen) | 1100 kg / 2200 lbs |

| Max bale weight | 1000kg / 2000 lbs |

| Min oil req. litres per minute | 18 l/min @ 150 bar |

| Electrical Requirement | 12v from Battery or EuroPlug |

| Working speed-table (up to) | 30 rotations/min |

| Film Holders | 2 |

| Protection Mechanism | Shear Bolt/ Roll Pin |

| Dispenser | 750/ 500mm @ 70% (55% optional) |

| Cut & Tie | Standard |

| Attachment to Tractor | Towbar |

| Control | Expert Plus

Radio Remote Control |

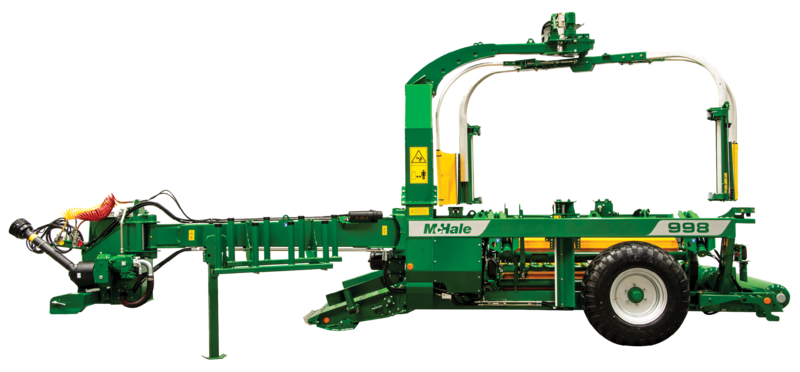

998 – Square Bale Wrapper

The McHale Square Bale Wrapper Range has been designed with the demands of today’s farmer and contractor in mind. This common-sense approach to design ensures that each machine’s operation is kept simple and user friendly, while delivering the highest output and reliability through the use of quality components, precision engineering and our patented oscillating rollers and patented roller angle measuring system.

Designed to provide greater operator comfort and flexibility whilst maximising output and reducing maintenance intervals, the McHale 998 range has become renowned and respected worldwide for bringing square bale wrapping to a new level.

Download Product PDF

Overview

The 998 square bale wrapper is a high-output machine packed with features including a fully integrated, PTO driven, load sensing hydraulics system, conveyor loading with fast positioning of the square bale into the bale wrapping position, hydraulically operated cut & tie system, auto square bale levelling and a two point linkage mounted swivel headstock.

It is equipped with two patents;

- Patented Oscillating Rollers – These cradle the bale during wrapping and steadily rotate the bale to ensure a uniform and correct overlap.

- Patented Roller Angles Measuring System – This ensure a consistent and even wrap regardless of square bale size or shape.

Bale Sizes

| Bale Size (minimum) | Bale Size (maximum) | Max Bale Length |

80cm X 60cm(2’8″ x 2′) | 120cm x 160cm(4′ x 5’3″)* | 2m(6’7″)** |

*including double square bales measuring 120cm x 70cm (4′ x 2’4″) in size.

**depending on bale profile and shape

Standard Features

| Fully Automatic Electronic Control | In-cab Control of Bale Size and Film Layer |

| PTO Driven Load Sensing Hydraulics | Hydraulic Drawbar Movement |

| Continuous Cycle Function (Load / Wrap / Drop Bale) | Patented Oscillating Rollers (for Even Wrap Application and Bale Rotation) |

| Automatic Bale Levelling | 2 X 750mm Dispensers |

| Hydraulic Cut & Hold | Film Break Sensors |

| Quick-Fit Dispenser Film Change | Film Replacement Loading Step |

| External Dispenser Index Button | 12 Roll Storage (10 in Storage and 2 in Dispensers) |

| Low Ground Pressure Tyres with Braked Axle | |

Technical Specification

| Transport Length | 7.3 m (24′) |

| Transport Width | 2.99 m

(9′ 8″) |

| Transport Height | 3.69 m (12′ 1″) |

| Weight (Unladen) | 4070 kg (8972 lbs) |

998 High Speed Square Bale Wrapper

The McHale Square Bale Wrapper Range has been designed with the demands of today’s farmer and contractor in mind. This common-sense approach to design ensures that each machine’s operation is kept simple and user friendly, while delivering the highest output and reliability through the use of quality components, precision engineering and our patented oscillating rollers and patented roller angle measuring system.

Designed to provide greater operator comfort and flexibility whilst maximising output and reducing maintenance intervals, the McHale 998 range has become renowned and respected worldwide for bringing square bale wrapping to a new level.

Download Product PDFOverview

The McHale 998 High Speed square bale wrapper contains all the features of the standard McHale 998. Through the use of Laser Sensors, the 998 High Speed dispensers can operate at speeds of up to approximately 40rpm. This increase in speed has the ability to deliver 35% more output over a standard 998 based on field test conducted in 2017.

The McHale 998 High Speed also comes as standard with an Adjustable Maximum Speed Setting. This allows the operator to set the speed at which they wish to work at depending on the bale size and quality of film being used. By choosing a setting on the control console, the operator can select a speed from 25rpm up to approximately 40rpm.

Bale Sizes

| Bale Size (minimum) | Bale Size (maximum) | Max Bale Length |

80cm X 60cm(2’8″ x 2′) | 120cm x 160cm(4′ x 5’3″)* | 2m(6’7″)** |

*including double square bales measuring 120cm x 70cm (4′ x 2’4″) in size.

**depending on bale profile and shape

Standard Features

| Fully Automatic Electronic Control | In-cab Control of Bale Size and Film Layer |

| PTO Driven Load Sensing Hydraulics | Hydraulic Drawbar Movement |

| Continuous Cycle Function (Load / Wrap / Drop Bale) | Patented Oscillating Rollers (for Even Wrap Application and Bale Rotation) |

| Automatic Bale Levelling | 2 X 750mm Dispensers |

| Hydraulic Cut & Hold | Film Break Sensors |

| Quick-Fit Dispenser Film Change | Film Replacement Loading Step |

| External Dispenser Index Button | 12 Roll Storage (10 in Storage and 2 in Dispensers) |

| Low Ground Pressure Tyres with Braked Axle | |

Technical Specification

| Transport Length | 7.3 m (24′) |

| Transport Width | 2.99 m

(9′ 8″) |

| Transport Height | 3.69 m (12′ 1″) |

| Weight (Unladen) | 4073 kg (8979 lbs) |

Pro Glide Mowers

McHale Pro Glide F3100 Front Mower

Every year McHale balers produce over 75 million bales of forage for farmers and contractors. To maximise the feed value of this forage it is important that grass crops are cut when the sugar content is highest, and that the mower leaves clean crop stubble and produces quality forage free from impurities.

Overview

The McHale Pro Glide F3100 Front Conditioner Mower suspension allows the cutter bar to move independently of the tractor’s linkage.

The McHale patented spring compensator ensures that cutter bar ground pressure is maintained over the 500 mm Vertical Travel Range and the cutter bar angle automatically adjusts up & down to the changes in the ground conditions

Standard Features:

| Tubular Frame with Integrated Suspension Design | Springs Provide Excellent Ground Following Ability | Automatic Bed Angle Adjustment |

| Patented Constant Ground Pressure | 17º Transverse Movement (Left / Right Movement) | 500mm Adaptive Range (Up / Down Movement) |

| Excellent Headland Height Clearance of Over 600mm | Foldable Guards Give Optimum Access to the Cutter Bar | Narrow Transport Width Provides Excellent Visibility |

| Pull Type Mowing System | ||

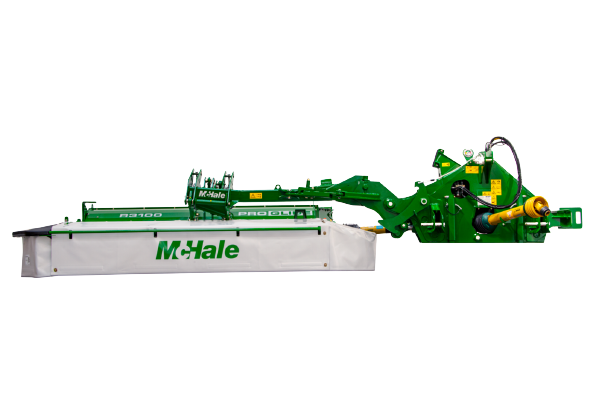

McHale Pro Glide R3100 Rear Mower

Every year McHale balers produce over 75 million bales of forage for farmers and contractors. To maximise the feed value of this forage it is important that grass crops are cut when the sugar content is highest, and that the mower leaves clean crop stubble and produces quality forage free from impurities.

Overview

The McHale Pro Glide R3100 Rear Conditioner Mower comes standard with our unique patented Ground Following Technology, break-back protection, hydraulic ground pressure control and heavy-duty cutter bar design making the Pro Glide a smart choice for farmers and contractors alike.

McHale have developed a unique patented ground adaption technology which delivers 3-dimensional ground contour tracking. This allows a left to right and forward and back arc of movement of the cutter bar. The cutter bar suspension works to deliver uncontaminated forage, achieving maximum performance and results for the farmer and contractor.

Standard Features:

| Mechanical Break Back | Springs Provide Excellent Ground Following Ability | Vertical Parking Stand |

| Patented Constant Ground Pressure | 17º Transverse Pivot Range (Left / Right Movement) | 12º (Forward / Back Movement) |

| Unique Cutter Bar Protection | 3D Ground Contour Tracking | 110º Transport Position |

| Pull Type Mowing System | ||

McHale Pro Glide B9000 Combination Mower

Every year McHale balers produce over 75 million bales of forage for farmers and contractors. To maximise the feed value of this forage it is important that grass crops are cut when the sugar content is highest, and that the mower leaves clean crop stubble and produces quality forage free from impurities.

Overview

McHale offer farmers and contractors a choice of combination mowers. The McHale Pro Glide B9000 is fitted with 3m cutter bars and has a cutting width of up to 8.75m when coupled with an F3100 front mower. The larger model, the McHale Pro Glide B9600 is equipped with two 3.4m cutter bars and can cut up to 9.6m when operating with an F3100 front mower.

All mowers are fitted with steel tine conditioners and benefit from several novel features resulting in better ground following ability and quicker reaction times to changes in ground conditions to deliver a clean cut with uncontaminated crop.

Standard Features:

| Springs Provide Excellent Ground Following Ability | Hydraulic Width Adjustment | |

| Patented Constant Ground Pressure | 17º Transverse Pivot Range (Left / Right Movement) | 12º (Forward / Back Movement) |

| Unique Cutter Bar Protection | 3D Ground Contour Tracking | Vertical Transportation and Parking |

| Pull Type Mowing System | ||

McHale Pro Glide B9000 Combination Mower

Every year McHale balers produce over 75 million bales of forage for farmers and contractors. To maximise the feed value of this forage it is important that grass crops are cut when the sugar content is highest, and that the mower leaves clean crop stubble and produces quality forage free from impurities.

Overview

McHale offer farmers and contractors a choice of combination mowers. The McHale Pro Glide B9600 is equipped with two 3.4m cutter bars and can cut up to 9.6m when operating with an F3100 front mower

The smaller model, the McHale Pro Glide B9000 is fitted with 3m cutter bars and has a cutting width of up to 8.75m when coupled with an F3100 front mower.

All mowers are fitted with steel tine conditioners and benefit from several novel features resulting in better ground following ability and quicker reaction times to changes in ground conditions to deliver a clean cut with uncontaminated crop.

Standard Features:

| Springs Provide Excellent Ground Following Ability | Hydraulic Width Adjustment | |

| Patented Constant Ground Pressure | 17º Transverse Pivot Range (Left / Right Movement) | 12º (Forward / Back Movement) |

| Unique Cutter Bar Protection | 3D Ground Contour Tracking | Vertical Transportation and Parking |

| Pull Type Mowing System | ||

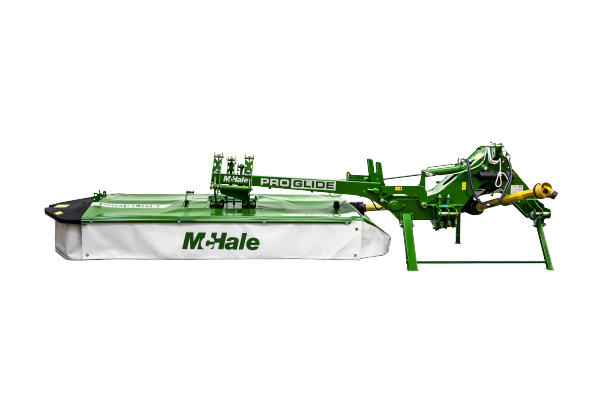

McHale Pro Glide R310 Non Conditioner Mower

For over 30, years the McHale range of grassland equipment has been operating on 6 continents in some of the worlds most difficult conditions. Building on their comprehensive range of mowers, McHale now introduce the McHale Pro Glide R310 non-conditioner mower. Following direct requests from the market, McHale’s design team have combined their specialist knowledge of crop harvesting, energy and technical know-how to develop the McHale Pro Glide R310 non-conditioner mower.

Overview

The McHale Pro Glide R310 mower has excellent ground following capabilities delivering superior floatation. The mower is fitted with a patented ground adaptation technology which delivers 3-dimensional contour tracking of the ground. This allows the mower to easily mow on rough or undulating terrain and still deliver optimal results.

Most rear mowers have a central pin which allows the mower to move left and right to adjust to changes in ground condition. The McHale Pro Glide is different in that it is fitted with a patented 3D ground tracking suspension unit, which allows the mower to:

- Move Left and Right

- Move Forward and Back

- Let the cutter bar move back and up if it collides with an obstacle.

This ensures that the Pro Glide cutter bar delivers better cutting performance.

Standard Features:

| 3D Ground Tracking Technology | Unique Forward/Back Movement of 12° | Transverse Movement of 17° |

| Unique Stone Protection | Mechanical Break Back Protection | Heavy-Duty, Fully Welded Cutter Bar |

| Heavy-Duty 1,000 or 540rpm Driveline | Low Profile Front Edge | Quick Fit Blades |

| 25mm (1′) Thick Gears | Adjustable Swathing Discs (Optional) | |

Contact Us At Histand's Farm Services Today.

At Histand’s, we’re here to help, whether its more information, pricing, parts, a quote, expert service & advice, we’d love to hear from you.

58 Potterville Rd, Rome, PA 18837