1415 Beeson Mill Rd, Leetonia, OH 44431

Brush Cutters

Next-Level Attachments for Clearing Brush

Which deck style is right for you?

- Open Front Skidsteer

- Closed Front Skid Steer

Open front brush cutters are built without a front chain curtain, so the blades are exposed to attack brush first before getting under the deck. Debris leaves the deck sooner, resulting in a quicker cut with less mulching and a rougher finish with larger pieces of debris left over. A front push bar has been added to push down trees and feed material into the cutter.

- Destroys larger material quicker and easier

- Cuts trees without pushing them over first

- More aggressive and allows you to selectively cut vegetation

- Easier to get thick, woody material into the cutter

- Focused on taking down larger trees and saplings and less on mulching

- Looking to attack thick brush

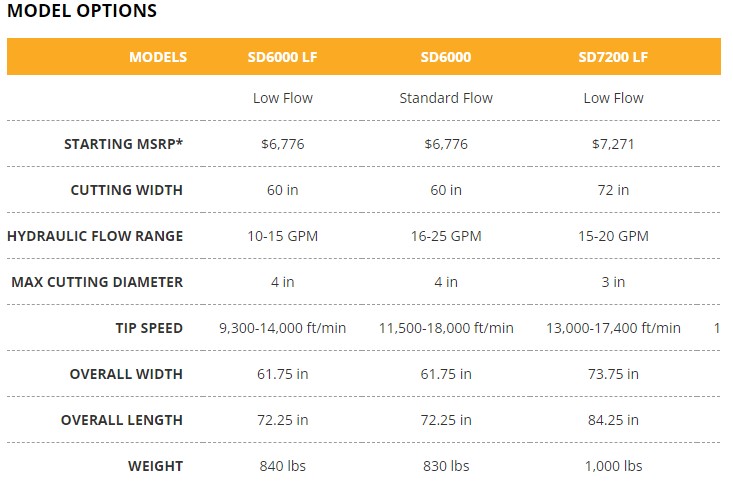

MODELS:

Cutting Width: 60” or 72”

Hydraulic Flow: 10-25 GPM

Tip Speed: 9,300-18,000 ft/mn

Max Cutting Diameter: up to 4”

Built lean and mean, the standard-duty series utilizes all the same drive and blade carrier components as our tried-and-true heavy-duty series but at a more budget-friendly cost. To make these cutters more economical, we removed the chain curtains, motor guard, and made a lighter support structure. The perfect cutter for those who do occasional clearing or have fewer demanding jobs. All standard-duty units are configured with the “open front” deck design that allows the blades to engage vegetation while the leading edge makes contact. Pound for pound, you won’t find a better value on the market.

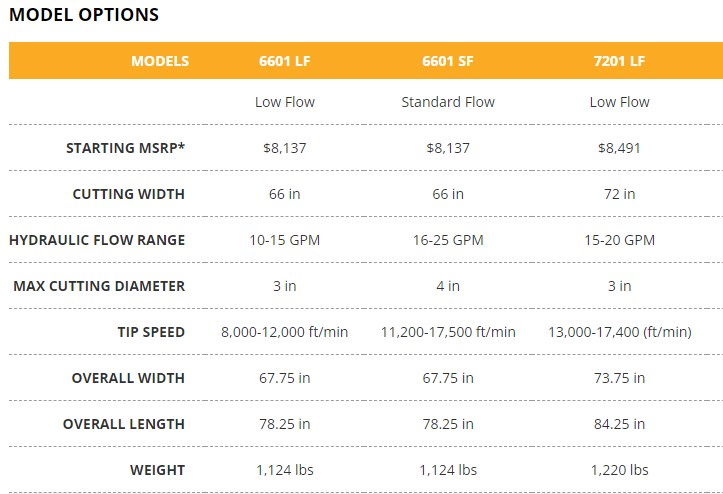

Cutting Width: 66”, 72″, 78″

Hydraulic Flow: 10-40 GPM

Tip Speed: 8,000-19,200 ft/mn

Max Cutting Diameter: up to 5”

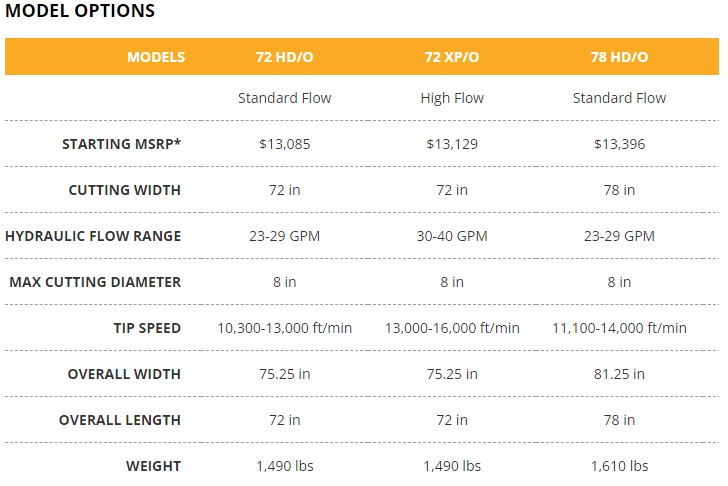

Cutting Width: 72” or 78”

Hydraulic Flow: 23-40 GPM

Tip Speed: 10,300-18,000 ft/mn

Max Cutting Diameter: up to 8”

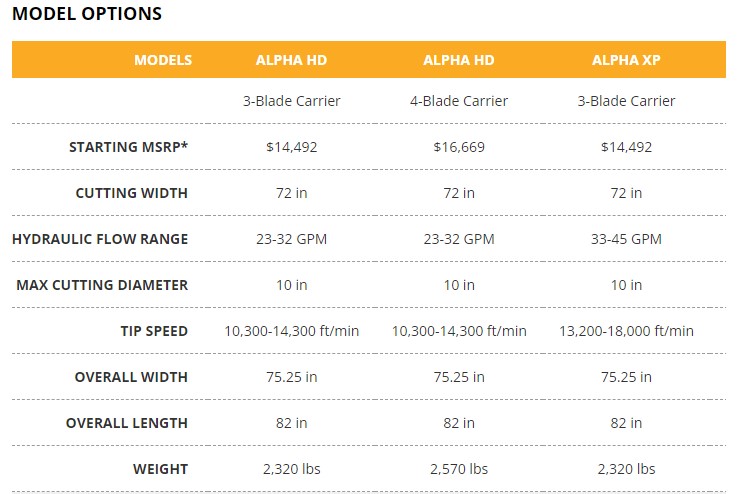

Cutting Width: 72”

Hydraulic Flow: 23-45 GPM

Tip Speed: 10,300-18,000 ft/mn

Max Cutting Diameter: up to 10”

Closed front brush cutters have a chain curtain that runs along the front of the deck, closing it off (thus the name “closed front”). Closed front cutters push vegetation down first before cutting it—keeping the cut material inside the machine longer. These types of cutters excel at clearing brush, weeds, undergrowth, saplings, and trees up to 5” thick.

- Chain curtain holds debris in for enhanced mulching

- Leaves a cleaner, more consistent finish

- Smaller, more manageable debris is left-over debris

- Safer as it prevents debris from flying out of the cutter

- Looking for a nice finish (parkland, pasture, golf course, recreational trails)

- Clearing brush along buildings and fence lines

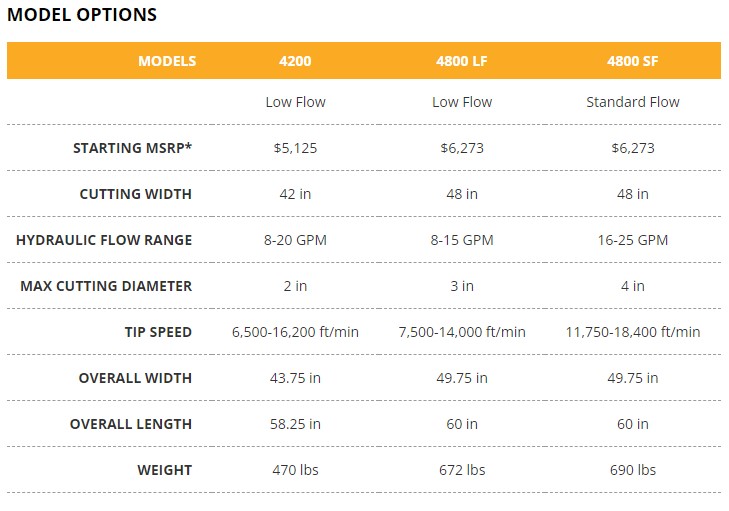

MODELS:

Cutting Width: 48”

Hydraulic Flow: 8-25 GPM

Tip Speed: 7,500-18,400 ft/mn

Max Cutting Diameter: up to 4”

Watch the video: https://youtu.be/IpSmnIv2cn8

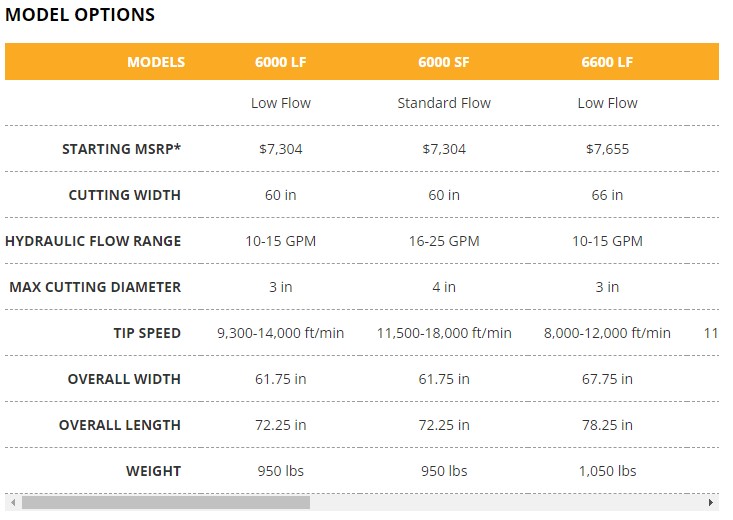

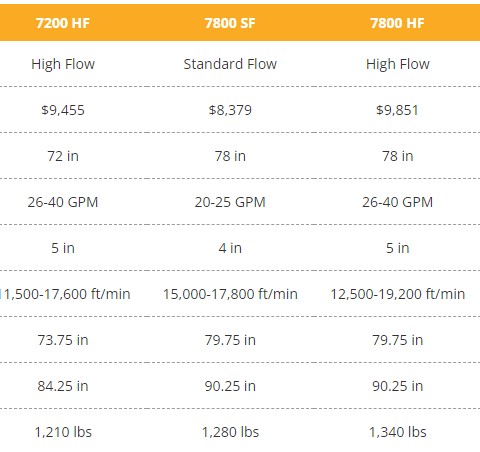

Cutting Width: 60”, 66”, 72″, 78″

Hydraulic Flow: 10-40 GPM

Tip Speed: 8,000-19,200 ft/mn

Max Cutting Diameter: up to 5”

Watch the video: https://youtu.be/PMn5iWnDEHo

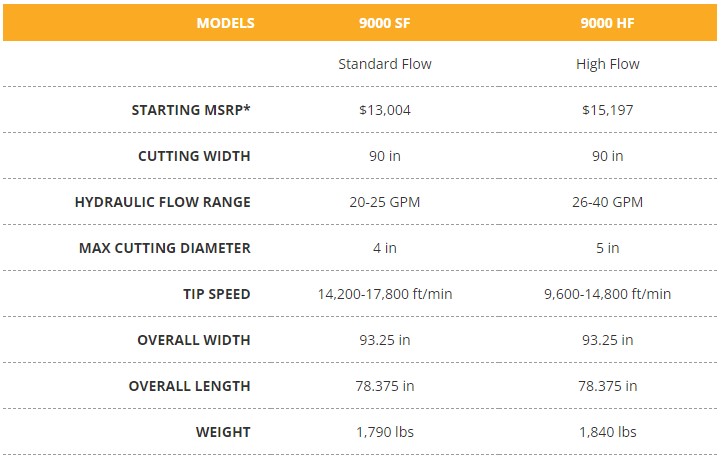

Cutting Width: 90”

Hydraulic Flow: 20-40 GPM

Tip Speed: 9,600-17,800 ft/mn

Max Cutting Diameter: up to 5”

The almighty 9000 can cut more in a single pass than any other rotary brush cutter. These extra wide machines provide a whopping 7.5 feet of complete cutting coverage, leaving no ground untouched. The multi-spindle design utilizes two separate motor/gearbox drive assemblies to power four high-strength tempered steel blades to quickly clear large tracts of land. One trip down the trail, and you’re done! You can quickly tackle any project with this hog. The added chain curtain in the front will keep debris in to aid in mulching.

Watch the video: https://youtu.be/dVqfw30bAHc

Often imitated but never duplicated.

- More structurally sound decks made from one piece thick steel

- Added reinforced gussets and bracing for increased strength

- Continuously welded deck for superior durability

- Powder-coated finish for ultimate durability

- Plug & play ready on delivery

- Hydraulic hoses, quick-connect couplers, and dust caps included

- Universal quick attach system for easy on and off

- Easy blade access for quick blade changes

- Parts are always available at www.brushwolf.com/parts

- High-tempered, industrial-strength blades

- Updraft lifts and mulches for a cleaner cut

- Non-updraft cuts material quicker

- Ultra-smooth blade carrier is CNC-balanced

- Compact, Standard, and Heavy-Duty cutters are built with the reliable Geroler-style hydraulic motor with a right-angle gearbox

- The Extreme-Duty and ALPHA series comes with a more powerful radial piston motor and robust bearing housing

- Everything is designed, engineered, and built under one roof here in the USA

- We support our local community through philanthropy and volunteering

- We’re proud to partner with local colleges and mentorship programs to help build our industry’s workforce

- 5-year limited warranty on the cutter’s structural components, materials, and weldment

- 1.5-year limited warranty on the hydraulic motor, gearbox, bearing housing, and cylinders

- Advanced pressure relief motor protection controls pressure spikes

- Grade 2 shear bolt saves the motor from impacts

- Higher flow models include case drains to reduce pressure fluctuations

- Welded collar around the gearbox seal protects it from damage

- Special protective wrap encases hydraulic lines for safety

- Added dust caps ensure longer motor life by decreasing possible line contamination

- Protective hoods or guards have been added to most models to shield the motor

- Shields are perforated for protection and increased visibility

- Chain curtains protect people and nearby structures from flying debris

- Lift limit chains prevent the cutter from being lifting too high

- Deflector plates on large cutters control the direction of discharged material

- Non-slip safety steps for easy in and out

Contact Us at Progressive Ag Rentals today!

We’re here to help, whether its more information, pricing, parts, a quote or expert advice, we’d love to hear from you.

1415 Beeson Mill Rd, Leetonia, OH 44431